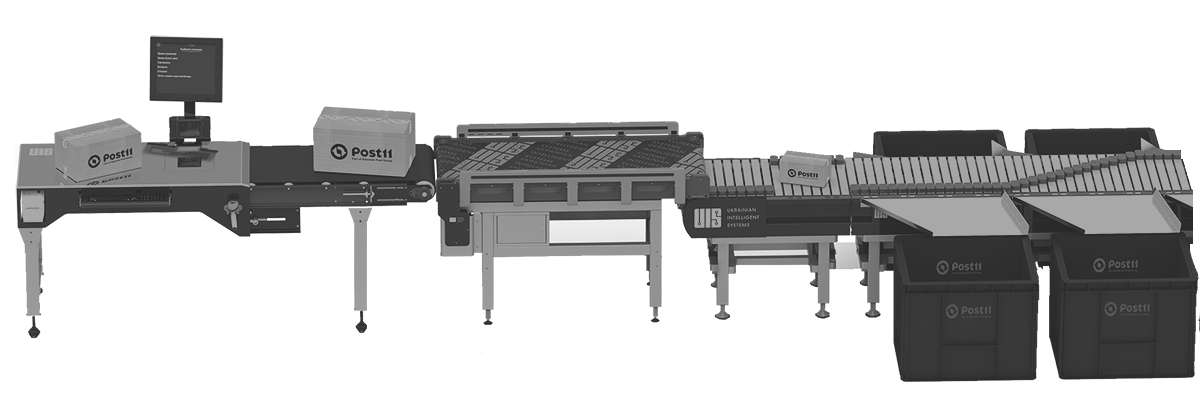

Sorting conveyor

The high-performance automatic sorting conveyor system of goods and cargo

Product feature

- High productivity (up to 5000 pcs / hour)

- Payback period of 1 year

- Sorting accuracy 99.99%

- Simple and reliable design

- Continuous work

- Adaptation to customer processes

- Minimum staff

System elements

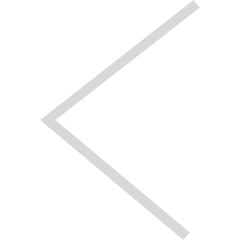

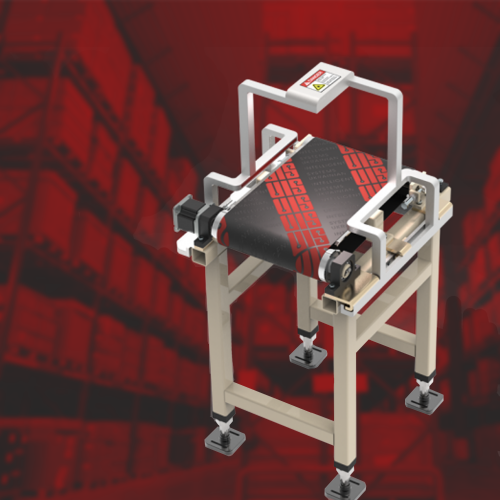

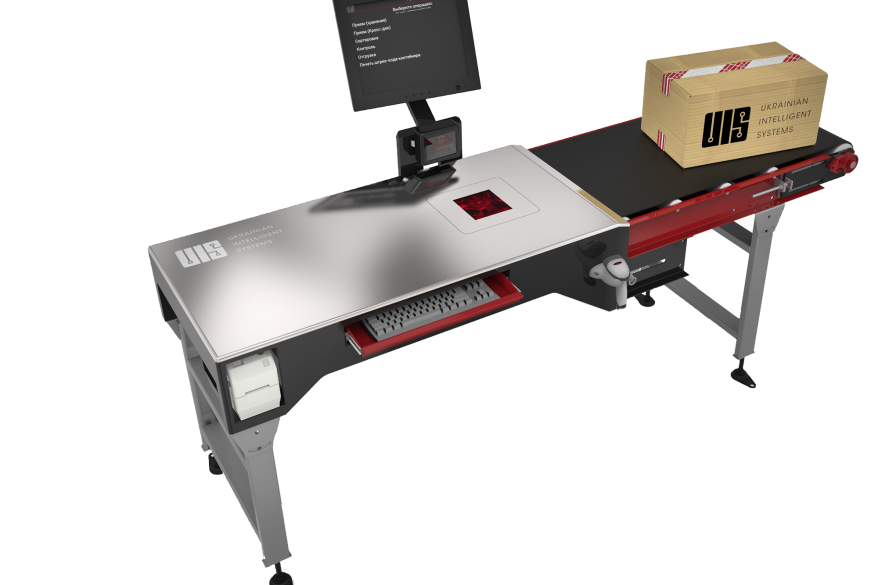

Operator’s workplace

It is the main operator’s workplace. It used for the initial identification of goods and relabeling (if necessary). Equipment:

- Stainless steel sliding table

- Conveyor belt (speed up to 2.5 m / s)

- Large screen

- Built-in barcode scanner (for quick identification of small cargo)

- Stationary barcode scanner (for medium-sized goods)

- Manual barcode scanner (for scanning jammed and large loads)

Weight meter

This unit of the conveyor complex is designed for weighing and forming the distance between objects before transportation to the sorting module. With the help of sensors, the meter determines the moment the object hits the tape, and when registering the end point of the object, it shifts it to the sorting line, thereby providing the necessary gap between the objects. Each sensor, except for the input one, has a duplicate beam to ensure the most effective conditions for stopping the tape.

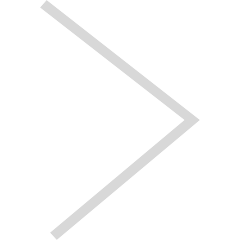

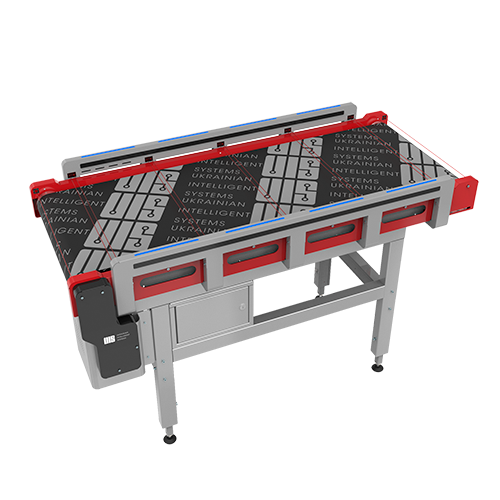

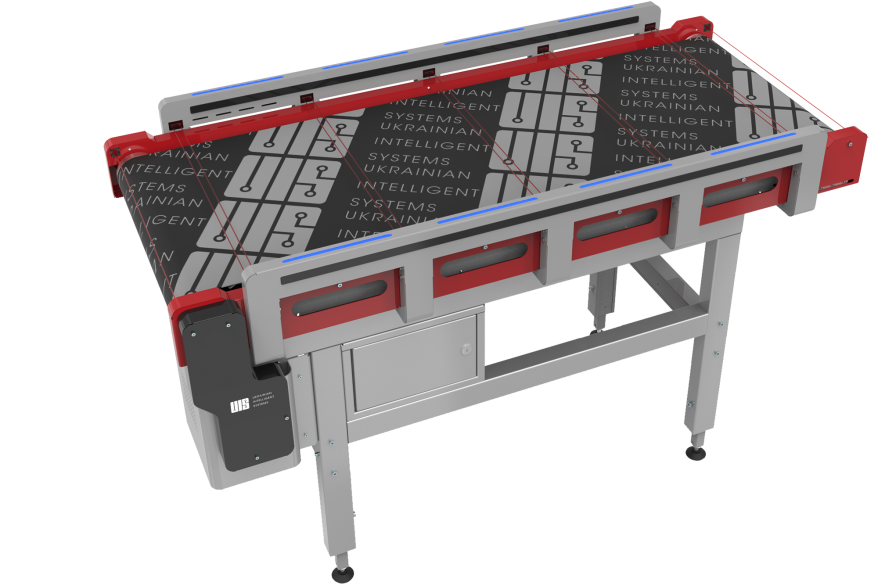

Pusher preparation

The sorting system includes a module for preparing movable lamella pushers. The module is located at the beginning of the sorting module. When placing objects on the sorting line, depending on the direction, it is necessary to shift a certain number of pushers in the appropriate direction. The technical and electrical characteristics of the preparation module correspond to the sorting module.

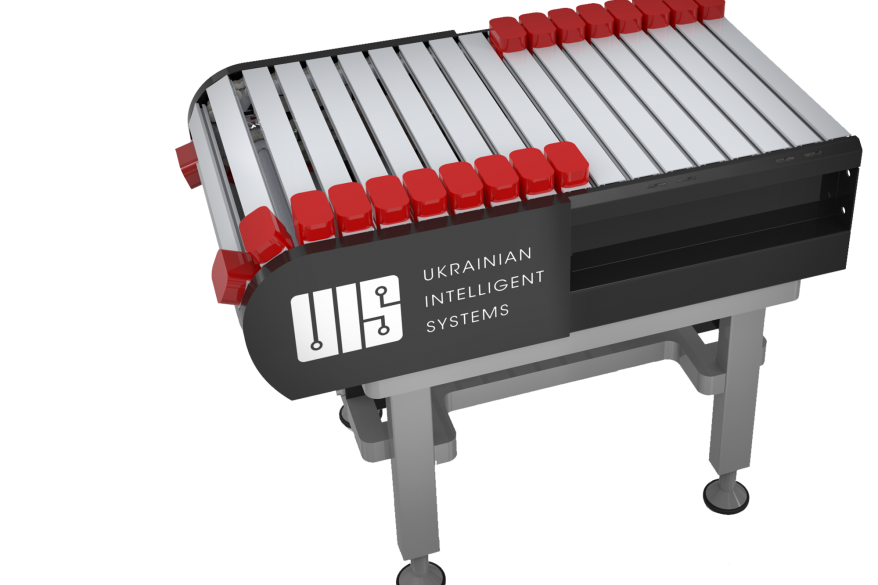

Sort module

The sorting line consists of series-connected transfer modules and a single transport platform consisting of parallel-connected aluminum lamellas. Each lamella contains a movable pusher, thanks to which the object is smoothly moved to the discharge port. The system can be equipped with roller gravity or roller drives. When ordering sensors of containers fullness, the sort module can signal an imminent container overflow.